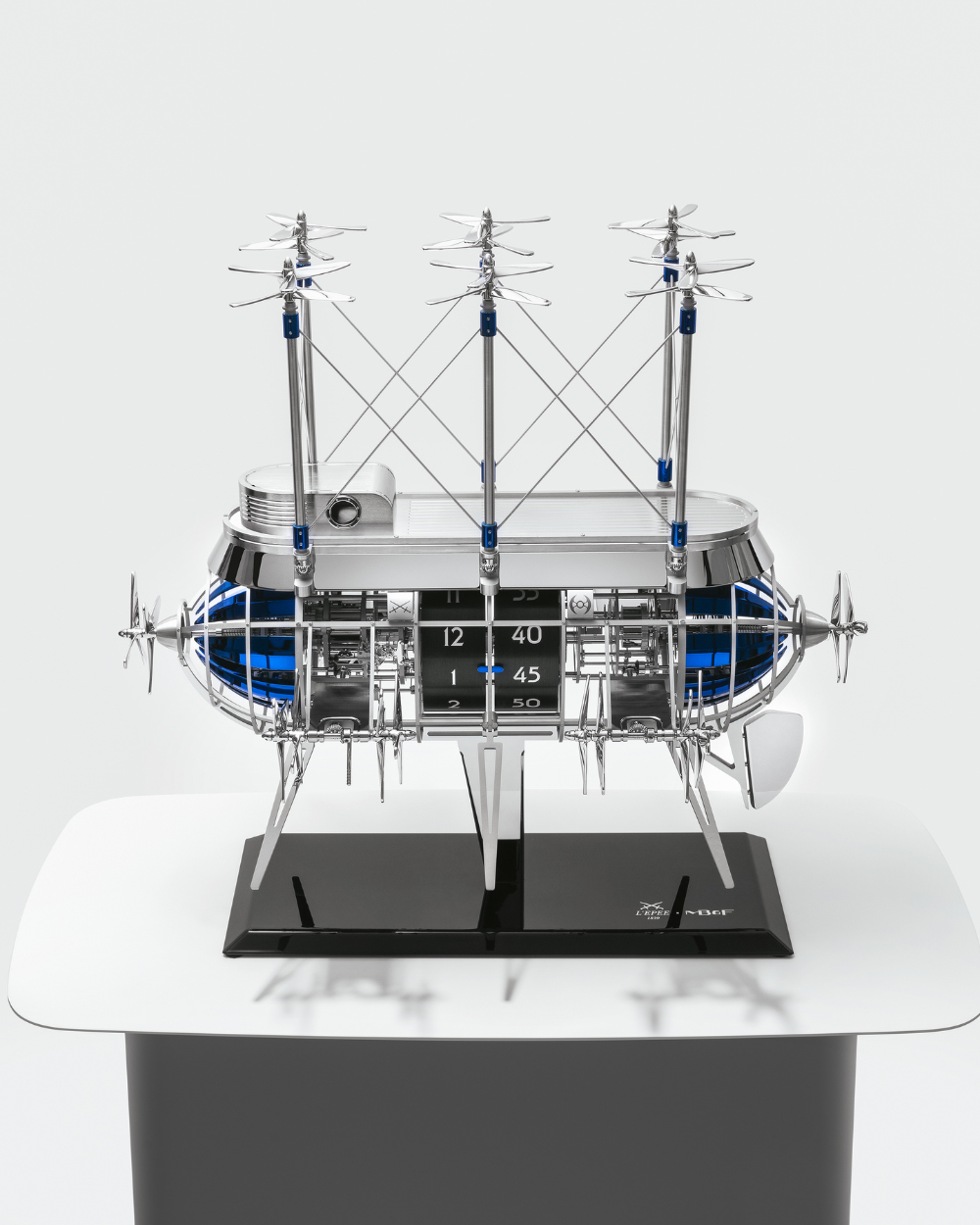

The Madness Continues ... An All-New L’Epée X MB&F Collaboration Arrives

15 clocks over 10 years, the relationship between L’Epée and MB&F runs deep. With each clock seemingly more creative and exciting than the last, we see this trend continue for Geneva Watch Days 2024. The most ambitious project yet, this is the all-new L’Epée x MB&F “Albatross.”

Totalling a whopping 1520 components, Albatross features a striking hour function – chiming both the specific hours on the hour and a single strike on the half-hour – and an automaton composed of 16 pairs of propellers that launch into action every hour. Roughly 15lbs, 2 ft long by 2 ft high and 1ft wide, the aircraft springs into action as the clock strikes the hours and prepares for take-off with its 32 rotating propellers that whirl for about seven seconds. The brainchild of designer Eric Meyer, this is the first ever “propeller hour” clock, further establishing L’Epée’s position as the king of ultra-creative mechanical automatons in timekeeping.

Inside the aircraft are two movements and two winding systems; one powers the time and striking hour, thanks to two separate barrels, while the other provides the energy for the propellers, powered by a third barrel. The first is manually wound via the propellers at the front of the flying machine: clockwise for the striking hour and anti-clockwise for the time. The propellers at the back wind the automaton. In terms of power reserve, the clock can run for an average of eight days – whether the chiming function is turned on or off – and the automaton for one day. By nature of the dual movements, it is possible to have the propellers turn without the hour chime, and vice versa. There are also two “on demand” buttons to chime the time and/or turn the propellers separately.

The clock is made from a mix of brass, steel, and aluminum and comes in a choice of five colors – blue, red, green, champagne, and black – all of which are limited to only eight pieces. The coloured parts are achieved using a translucent cold lacquer, a little like enamel, which allows the different finishing techniques to be perceived beneath. This coloring technique offers a superior depth compared to typical anodising treatments, and took L’Epée years to perfect.